|

Linear actuators receive accolades for their versatility. They have many applications, from home automation to manufacturing, automotive, aerospace, and medical industries. But they are not problem-proof.

Sometimes, linear actuators suffer faults that affect their performance. We’ll discuss the three most common ones and also some workable solutions to fix them:

-

Failure to Extend or Retract

Source: teknic.com

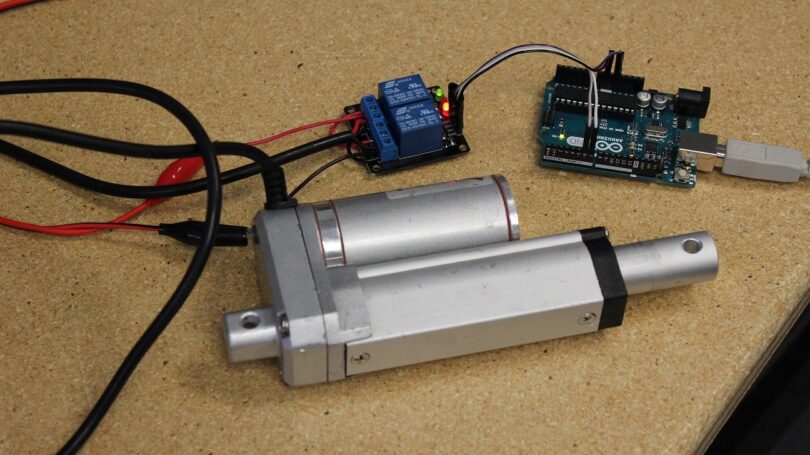

A linear actuator’s basic function is to create linear movement. The device’s control system adjusts motion to match its stroke length. And for that, it needs to extend and retract. If a linear actuator doesn’t perform these two activities, then, it’s not working.

It’s a common problem with several probable causes. The device may fail to extend or retract if the wiring isn’t accurate or some loose connections exist. The problem can also stem from incorrect polarity and a low power source.

A possible solution to the issue is to first check the power source and ensure it’s enough for the actuator. You’ll know whether power is adequate by measuring the current output. A digital multimeter or voltmeter will work.

Should the issue persist, check the wiring connections. If it’s an electric actuator, try changing the direction of the current flow to reverse polarity.

-

Premature Failure

Another common problem you could experience with linear actuators is premature failure. You’ll hardly hear about the lifespan of an actuator device. This is because there’s no hard figure. The lifespan depends on the device’s programming and speed capabilities.

Nevertheless, a linear actuator should serve for over 100 million cycles. Premature failure occurs when the device doesn’t last up to its lifespan. It’s likely because the actuator suffers from excessive loading, side loading, and pour mounting.

So, to avoid premature failure, only use the device for its specified load capacity. Also, check that it’s mounted the right way. And it’ll help to conduct checkups and maintenance from time to time.

-

Saturation Issues

Source: firgelliauto.com

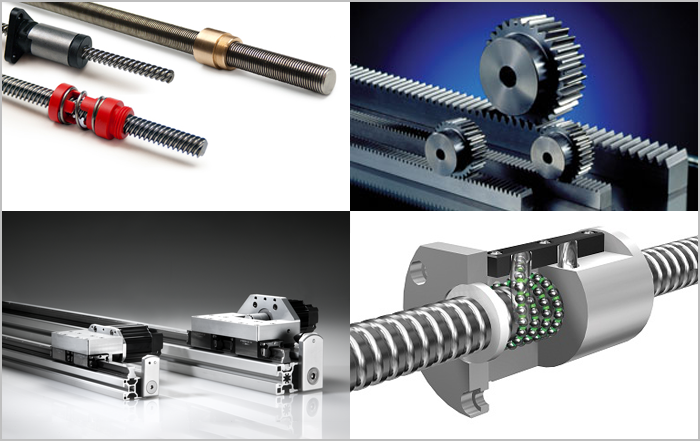

Is your linear actuator control system outputting more than the device’s capabilities? It means it’s experiencing saturation, which is a serious problem.

Saturation can cause permanent damage to the linear actuator or the system it operates. In milder situations, it’ll reduce performance or cause non-linear movements.

This problem can happen due to external disturbances. For instance, you installed the linear actuator in an environment that exposes it to harmful elements. If that’s the case, switching the location to a saturation-resistant one is a quick fix. Another option is installing robust controllers that better handle external pressure.

In some instances, saturation may be due to actuator imperfection. That is, the device has a faulty design from the manufacturer. Usually, the solution is a complete replacement.

Conclusion

Your linear actuator may suffer different problems. The three most common to look out for are:

- Inability to extend and retract

- Saturation issues

- Premature failure

The above can seriously impact how the motion devices work. But it doesn’t have to end their operations. With the information in this post, you should be able to fix the problems and get the device working again.