|

There are a lot of components that come together to build a truck. Whether we are talking about a heavy truck or a standard everyday delivery van, the systems that combine to make things safe, secure and reliable are varied. You may think of a truck as something of an agricultural nature, perhaps not as sophisticated as your road car. You would be wrong, as trucks are some of the most complex vehicles on the roads today.

This is because they have to do a specific job, and it’s not as simple as just driving to the shops or the office or doing the school run! A truck has to take on a lengthy journey on a regular basis with a heavy load, and it has to be reliable to do this over its lifetime. The engine, the brakes, the chassis, gearbox and the wheels are just the obvious parts of a truck, but there are more intricate components that perform equally important jobs.

Take the wheels: we know they are powered from the engine by driveshafts and other in between parts, but how are they held onto the axles? This is where the hub assembly comes in, and it’s what we’re going to explain in a moment. We’ll also talk about some other components that are essential in keeping a truck on the road. Let’s begin with a piece about hub assemblies.

The Hub Assembly Explained

The wheel hub assembly was apparently invented in the 1930’s prior to which wheels had been directly attached to the axle. Citroen, ever the pioneering brand, are believed to have been the first to use such an assembly on their Traction Avant model. At Finditparts.com you’ll find details of many different wheel hub assemblies for a variety of trucks, so what is it, and how does it work?

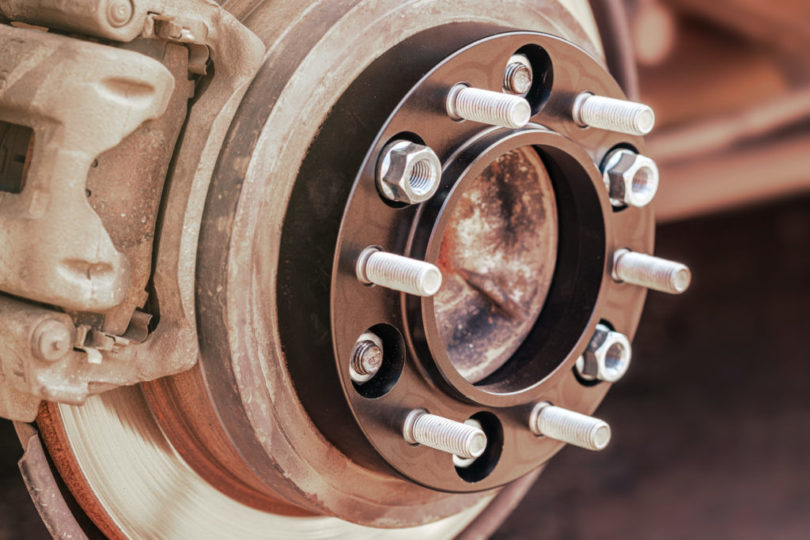

A wheel hub assembly sits between the axle that is driven, and the disc or drum brake set up. If you have ever changed a wheel, when you bolt it back on those bolts are attached to the wheel hub assembly. On the other side – inside, if you like – the assembly attaches to the knuckle that is part of the steering system. The idea is that the entire assembly – complete with the brakes – turns with the steering. The hub assembly is considered part of the steering system.

Of course, that on a car will differ from that on a truck. A wheel hub assembly consists of a number of parts including bearings for ease and efficiency of movement. It is a sealed unit and cannot be taken apart and repaired if broken. Instead, a damaged or broken hub assembly is simply replaced entirely.

The assembly is one of the hardest working parts of a truck as it is constantly moving. This is why a regular service will often include replacement of such parts as a precaution. In short, then, what the hub assembly does is keep your wheels attached to the vehicle, allows them to spin freely, and also to turn as the steering instructs.

In most trucks the hub assembly will also include sensors that activate the ABS. This is the anti-lock braking system, a safety innovation that is perhaps one of the most important developments in road transport. The sensor will constantly measure the speed of each wheel so that it can activate the braking control that keeps the vehicle in a straight line and brakes evenly across the wheels. These sensors also activate traction control if it is fitted to the vehicle, and most trucks do have a TC system. It is important to understand how to know when a hub assembly is tired, worn or damaged, and needs replacing, so let’s talk more about the tell-tale tale signs you need new hub assemblies.

When to Change Your Hub Assemblies

Source: carparts.com

When it comes to truck safety USA authorities are very strict about what is and is not permitted. Checks on vehicles are carried out on a regular basis and any faults or problems need to be rectified as soon as instructed. Given the numbers of trucks on US roads this is a full-time process that is ongoing, and one that is carefully orchestrated, and the rules on truck weight limits are also administered carefully.

Now, as a car driver you notice when things don’t feel right: perhaps you get a vibration telling you something is wrong or a strange noise that wasn’t there before. You may think this would be difficult when driving a heavy truck but in fact truck drivers become surprisingly ‘in tune’ with the vehicle and notice things very clearly.

Hence, they will be aware of problems with the wheel hub assembly should they hear or feel any of the following:

- The wheels start emitting unusual sound when the speed reaches a certain point – perhaps 40mph – that is ongoing and does not stop. This is usually a grumbling, squeaking or whining sound and is instantly noticeable.

- The steering begins to shake at a set speed in a way that is contrary to the usual. This is a sure sign the bearings in the wheel hub assembly are failing.

- The ABS warning light comes on when driving normally, indicating a sensor failure or other problem with the system.

Truck drivers are well versed in common problems and the wheel hub assembly is one of the first components that will be checked when such problems occur.

Conclusion

All trucks – indeed all 4 wheeled and more road vehicles – rely on wheel hub assemblies, and in later vehicles hub assemblies will be found on all wheels, not just the steered wheels. This is for ease of replacement, as it is wise to fit new hubs all-round if there is a problem with just one.

These clever units are readily available as replacement parts from leading spares suppliers and manufacturers and should be checked at every service interval and whenever the truck covers a certain mileage as they are essential for the safe operation of the vehicle.